Manual or Automated Compounding?

When life depends on less than a milliliter, there is no room for human error

Parenteral nutrition (PN) regimens are complex medications containing many macro- and micronutrients in various volume combinations ranging from 100 ml - 4,000 ml for children and adults. They are available as ready-to-use formulas or patient-specific preparations, e.g., for oncology patients or patients with renal or hepatic insufficiency and they can be prepared either manually or automatically with a compounding device.

Especially for premature and newborn infants, the requirements might be adjusted daily, making precise work absolutely essential to avoid dosing errors – the most common medication error in children.1, 2 Accurate delivery is one of the main advantages of automated compounding devices compared to manual preparation.

In addition to accuracy, time is also an important factor, as many hospital pharmacists must prepare 25, 30, or more bags each day. With manual compounding, this task is even more time-consuming than with the help of an automated compounding device.

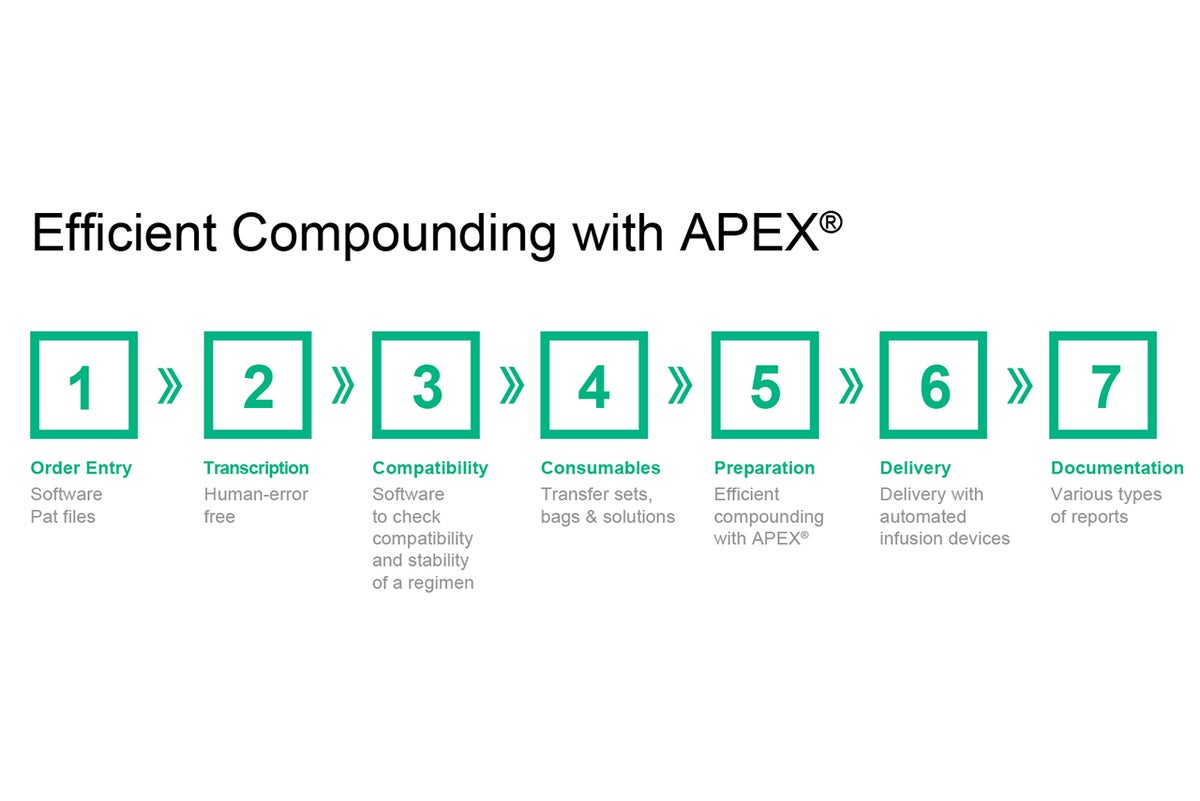

Efficient Compounding with APEX®

APEX® is an automated compounding device (ACD) that has been designed to meet the most critical patient and user needs with:

- large user interface for ease of use,

- dual drive to save time and increase accuracy,

- preassembled, barcoded, and color-coded transfer set to increase safety and save time,

- comprehensive portfolio of bags and disposables in an attractive package to facilitate the process of parenteral nutrition compounding.

Elevate your compounding with APEX®.

Pharmacists' Partner throughout the Entire Compounding Process

Order Entry

The process of parenteral nutrition starts with a prescription. B. Braun’s nutrition management software Clinus simplifies and optimizes the prescription of clinical nutrition and offers a closed loop from prescription to administration. The software can be connected to your hospital information system (HIS).

Transcription

When transcribing the composition of the regimen from the label to the mixture, the error risk is particularly high. APEX® can read and process prescriptions derived from several established prescription software writing PAT-files or QR codes with the regimen on the label and therefore reduce the risk of transcribing errors. The B. Braun software Clinus writes the composition of the regimen as a QR code on the label.

This simplifies the process of parenteral nutrition in a closed loop from prescription to administration, and if connected to a hospital information system, it also includes the documentation to ensure a human error-free transcription of the regimen and eliminate an important risk factor.

When transcribing the composition of the regimen from the label to the mixture, the error risk is particularly high. APEX® can read and process prescriptions derived from several established prescription software writing PAT-files or QR codes with the regimen on the label and therefore reduce the risk of transcribing errors. The B. Braun software Clinus writes the composition of the regimen as a QR code on the label.

This simplifies the process of parenteral nutrition in a closed loop from prescription to administration, and if connected to a hospital information system, it also includes the documentation to ensure a human error-free transcription of the regimen and eliminate an important risk factor.

Compatibility

Compatibility is a crucial point for patient safety. Parenteral nutrition regimens are complex mixtures, and it is difficult to predict whether the prescribed mixture will be compatible and stable or not. Since the prescriptions are according to the patient’s needs it is the pharmacist’s responsibility to assure that they can be mixed and administered safely. With B. Braun’s compatibility software EasyComp the pharmacist can check compatibility and stability of a regimen before he or she prepares the mixture. If compatibility is not confirmed, EasyComp allows corrective measures to make the mixture compatible. If compatibility is confirmed, provides a stability statement, shelf life, can print labels, worksheets, and prescription sheets if necessary.

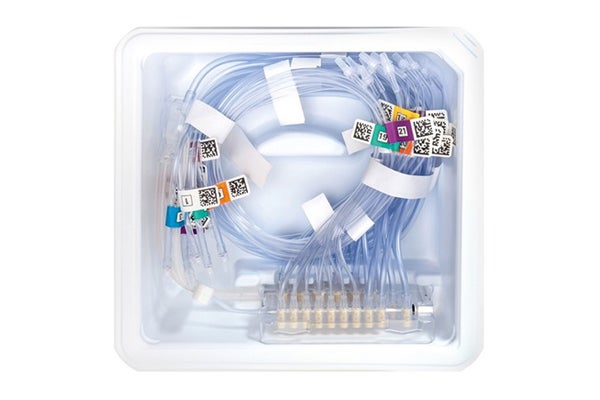

Consumables

26-Lead numbered Transfer Set

26 ports minimize the number of ingredients to be added manually. The transfer set is pre-assembled for easy and fast set-up and to avoid any touch contamination when assembling a set. It is barcoded, color-coded, and numbered to avoid mix-up of solution lines. The set comes with seven flex lines, which allow the dispensing of solution in the macro- or micro-line from the same source container, depending on the volume to be dispensed. For volumes less than 10 ml, it is pumped through the micro line, for volumes larger than 10 ml, it is pumped through the macro line, which is up to six times faster.

A broad range of bags

- EVA bags from 250 ml to 4,000 ml as mono layer bags are made of a highly transparent single-layer tubular sheet of EVA (ethylene vinyl acetate) for the storage of standard TPN regimens.

- Dual chamber bags from 1500 ml to 4,000 ml are made of a highly transparent single layers EVA tubular sheet with a double chamber compartment to maintain lipids and dextrose / amino acids in two separate chambers during transport and storage. By separating the lipid emulsion during compounding, the shelf life of the regimen can be prolonged.

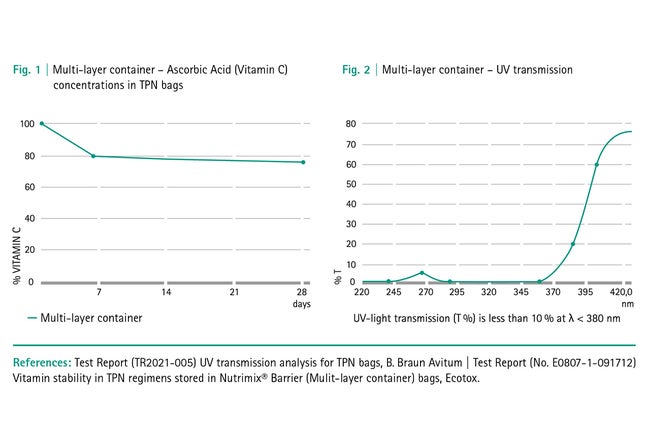

- Multi-layer bags from 250 ml to 4,000 ml are composed of a special multi-layer barrier film made out of EVA / EVOH (ethylene vinyl alcohol) / EVA providing an excellent oxygen barrier. These bags were developed to protect oxygen-sensitive nutrients as vitamins from oxidation. This protects the regimen in the bag and leads to a longer shelf life. UV protection has also become of special importance for pediatric and neonatal regimens.

Easy-Clip Vial Holders

for comfortable accommodation of the small volume ingredients according to the users’ preference. They are easy to attach and remove and available for vials from 10-100 ml and clips for syringes.

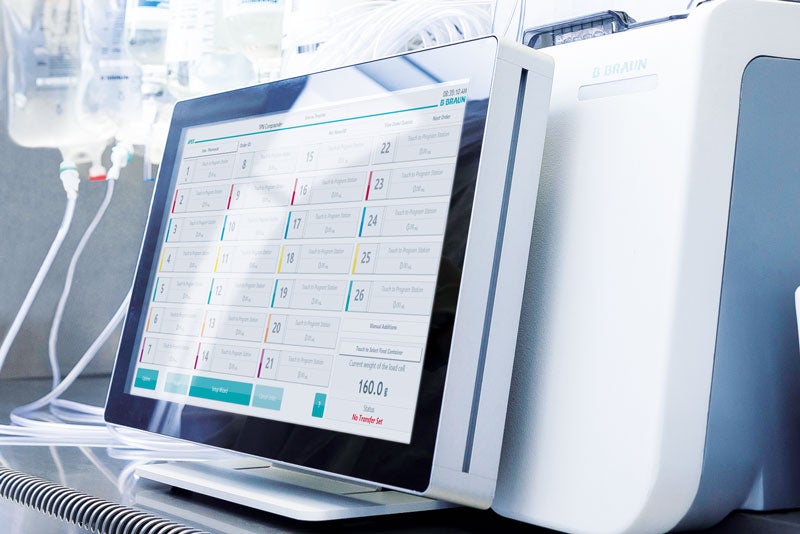

Preparation

APEX® is a compact, state-of-the-art compounder with latest technology for preparation of various solutions. It comes with

- 26-port transfer set

- vial rack directly at the compounder for comfortable direct accommodation of ingredients

- large and flexible 16-inch user display. It can be placed either directly in front of the compounder, anywhere else in the laminar airflow, or even outside, if necessary. APEX® has the largest user interface currently available.

- wireless barcode scanner to reduce the cables in the laminar airflow. The barcode scanner allows the station and solution verification by scanning the barcode on the line and on the source container.

- load cell for gravimetric verification that can be adapted to vertical or horizontal flow in the laminar airflow.

- dual-drive filling technology, which can dispense micro- and macro solutions at the same time.

- manual additions. All solutions which are on the label but are not hanging on the compounder are automatically listed in the manual additions. The user can track and verify the dispensing of manual additions. This way, no manual addition gets lost anymore, if a solution is not hanging at the compounder.

Delivery

Around the APEX® compounder, B. Braun offers a complete package for the process of compounding of parenteral nutrition – from order entry to final documentation. We have software for order entry, provide barcodes for error-free transcription, we offer compatibility software, a comprehensive set of disposables, fast, reliable, and accurate preparation, delivery, and documentation.

Documentation

APEX® offers a variety of reports for the pharmacist:

- Authorization reports

- Compounder event and activity reports

- Compounding precision reports to check accuracy of delivery

- Usage reports for containers and solutions (per day / week / month / year) to improve stock management and auto-processing

- Solution usage report based on a lot base to be able to track which solution has been delivered to which regimen

Compounding of Parenteral Nutrition

The main benefit of an automated compounder is, that it reduces the risk of human error because the transcription of regimens is read out electronically with a barcode scanner directly from the label and it provides a higher accuracy of delivery. Automated compounding is also less labor-intensive allowing for more daily preparations.

If the compounder is connected to a hospital information system, direct electronic filing and documentation are possible.

Automated Compounding System

References

1 Miller MR, Robinson KA, Lubomski LH, et al. Medication errors in paediatric care: a systematic review of epidemiology and an evaluation of evidence supporting reduction strategy recommendations. BMJ Quality & Safety 2007;16:116-126.

2 Cowley E, Williams R, Cousins D. Mediaction errors in children : a descriptive summary of medication error reports submitted to the United States pharmacopeia. Current Therapeutic Research 2001;62(9) :627-640.