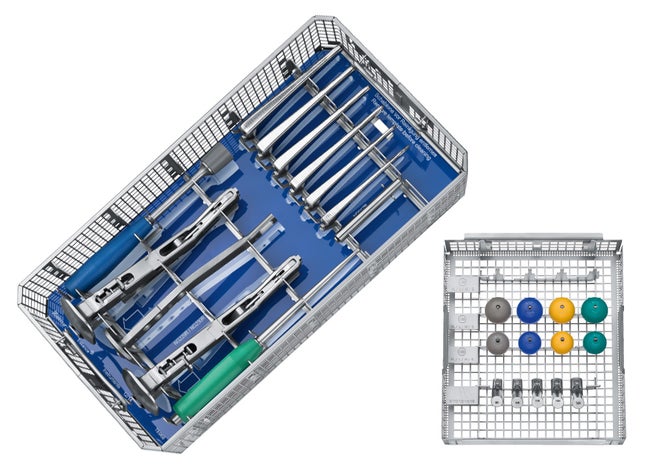

Trilliance® Hip Stem System

Triple tapered. Polished.

The philosophy of the Trilliance® triple tapered polished hip stem is a design evolution of this type of cemented hip stem prosthesis. The design philosophy of polished hip stems aims towards a minimization of cement damage. Tapered surfaces and the absence of a collar allow the hip stem to subside within the cement mantle, maintaining a compressive load transfer between prosthesis and cement and also between the cement and bone interface.

Since the beginning of cemented hip replacement considerations to use polished implant surfaces were taken to reduce the mechanical load and stress transfer to the bone cement.

Learn more about

Design

The Trilliance® hip stem is designed for cemented implantation. The design features are based on the third generation of straight polished hip stems.

The polished Trilliance® hip stems are triple tapered and produced from forged CoCr alloy. Trilliance® implants provide a linear increasing lateralization by implant size. The CCD is 135 deg.

Trilliance® implant size parameters increase proportionally by size. The mechanical strength of the design features is proven by mechanical fatique testing.